Lakoniya

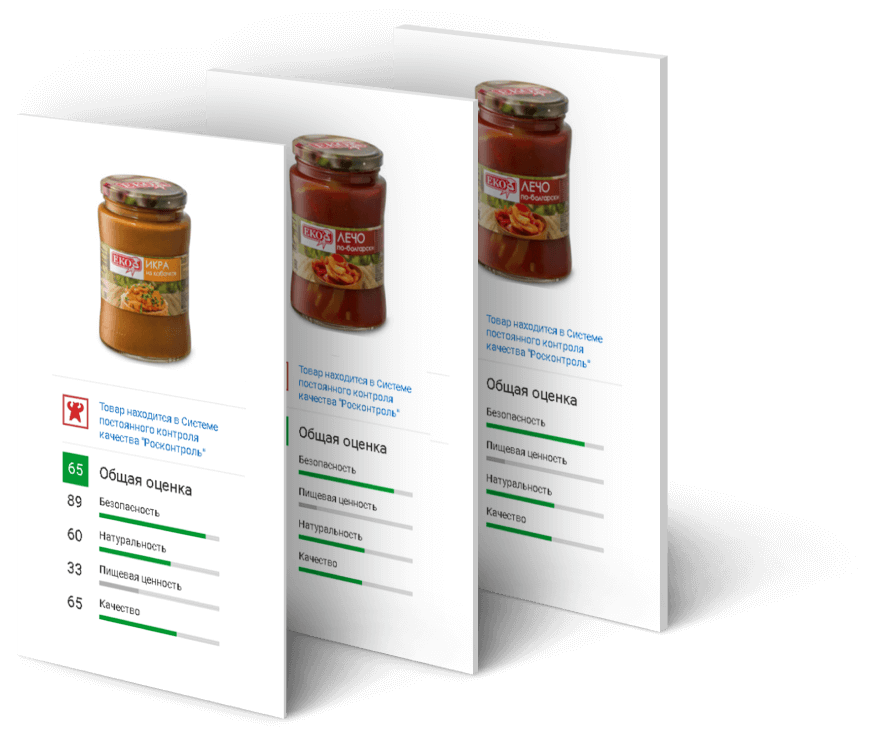

We have been manufacturing and supplying canned vegetables of the highest quality for more than 25 years to all regions of Russia, the CIS, and abroad

Watch the video

Mission

To develop and manufacture healthy products based on the processing of vegetables.

Goal

To become a leading manufacturer of healthy and delicious food

Team

Our team - is the main value of the company. We set the most daring goals and achieve them together. We value respect and support each of our employee to show their talents and to enhance their self- develop

Social projects

How it all began

1996

2006

2007

2008

2009

2011

2013

2017

2017

2018

2019

2020

2021